Microsoft recently announced that it is developing microfluidics heat dissipation technology, allowing coolant to flow directly through the wafer to reduce temperature by etching tiny pipes in the wafer. This structure idea is described as a new wave of cold revolutions, attracting attention from the market; if it can be truly implemented, it will have the opportunity to skip existing heat dissipation parts such as uniform heat sheets and water-cooled plates, and the affected Taiwanese factories include Jiance, Qilin, Dual Duck, etc. However, the industry believes that this technology is still quite far from commercially changing, and it needs to be applied in semiconductor processes and data centers, and the challenge is far more stringent than laboratory data.

The industry proposed that the technical challenge lies in how the chip microflower is introduced into the cold liquid, bonding different materials without leakage, and long-term movement is not affected. As CoWoP packaging heat dissipation scheme has been proposed in recent years, this scheme can also cancel the Heat Spreader on the wafer to shorten the heat dissipation path. However, because the Heat Spreader also undertakes the function of preventing the wafer from being curled and deformed, if completely removed, additional design brackets or pressure plate structures must be strengthened. This shows that if the industry chain wants to welcome the new heat dissipation mode, it is not only a replacement of a single component, but a comprehensive restructuring of the system architecture and supply division.

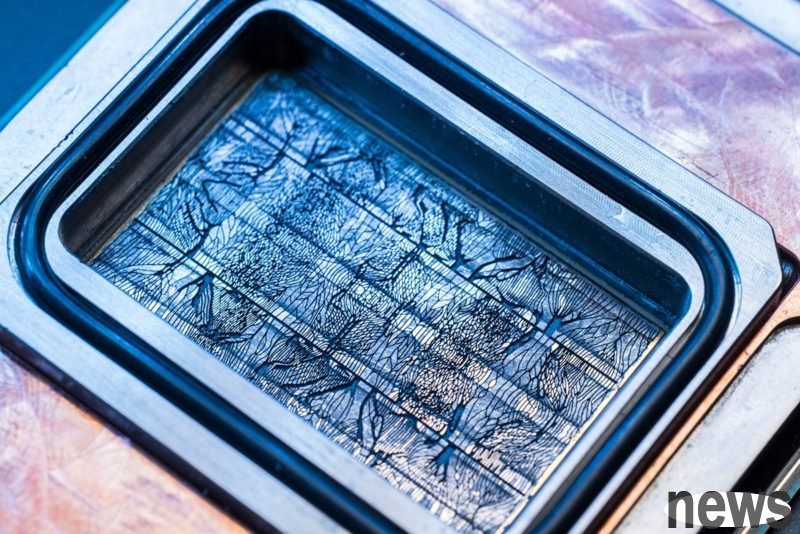

▲ The microfluidic chip developed by microsoft has a sieve and is connected to a pipe to ensure the safe flow of the coolant.

The industry pointed out that in the AI military competition, CSP factories do not want to fall behind. The new microfluidic exciting solution proposed by Microsoft has a breakthrough in its effectiveness, but it should not be easy for other businesses to give up their existing routes. This solution may only be applied in a small amount within the microsoft system, which will not result in industry standards. In contrast, the current chip scattering evolution has clearly taken a path, from 3D VC boards to water cooling solutions, and the next generation may evolve to Micro channel Lid. These designs have both reliability and are more likely to be used in the industrial chain.

Extended reading: New solution to reduce temperature of AI chips! Micro-File is experimenting with "microfluidic" heat dissipation technology